Perlite Expansion Technology

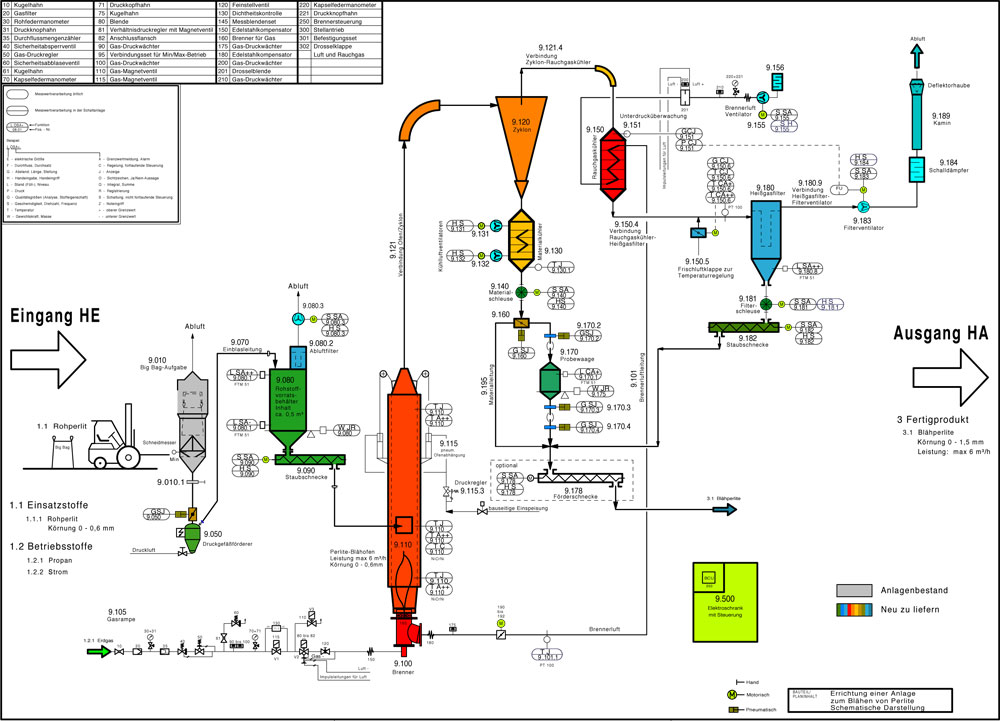

Raw perlite ore is delivered with big bags and directly blown through a fill pipe into the crude perlite storage tank. Via the dosing weigher crude ore enteres a distributor and from there is fed via two inlets into the blowing furnace. The furnace unit has a basic form of a vertical hollow cylinder resting on its base and having an open and high working space.

In the shaft furnace, the crushed perlite rock is quickly heated to a temperature above 1,000°C, at which point it begins to soften to a plastic state where the entrapped combined water vaporizes. This thermal process causes the material to expand, whether it changes its volume. Perlite grows up to 15-20 times its original volume and has a bulk density from 50 to 120 kg/m³.

An airflow removes expanded perlite upstairs out of the furnace and transports them to a cyclone. In the cyclone separator system the expanded perlite particles are separated from the airflow, then cooled down to approx. 100°C in the material cooler and discharged via the rotary valve.

The transportation of the expanded perlite is to be carried out pneumatically or, at best, mechanically, via belt conveyor, screw and elevator.