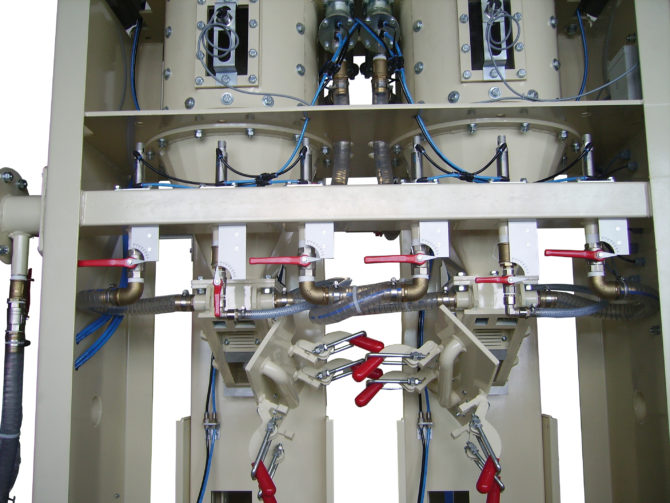

Air Bag Filling Machines

Our air packers Type BFM-A cover automatic inline and rotary packing machines for filling products into valve-bags.

Turbinen-Abfüllmaschine BFM-T

PRINCIPLE OF OPERATION

Via the feed hopper the product reaches in front of the cone lock. By opening the cone lock pressure chamber will be filled up to the maximum level. The filling process will be started automatically by opening the slide system, once a valve bag is put on the fillig spout – either manually or by using an automatic bag application. In order to avoid the bag „falling down“ from the filling spout during the filling process, a bag holding cylinder and a corresponding bag holding rubber are used to fasten the bag. By the use of air the product is conveyed from the pressure chamber into the turbine housing and finally delivered through the filling tube into the fixed valve bag. After the desired bag weight is achieved, the weighing machine starts to tare. Therewith the slide system will be closed and the filling process will be finished.

Is used for products: mortar and special mortar, soda, plaster, fish meal, S-PVC, adhesives, food or powders.

Relevant are grain size and flow properties of packing material, these should be the key reasons for your buying decision.

Basically the following applies: the more coarse-grained the product, the more suitable is the air packer for the filling.

Recommended value: for the grain size from 2 to 8 mm an air packer should be used.

TECHNICAL DATA

- Number of filling modules: 1 bis 12

- Filling capacity per modul: up to 350 bags/hour (depending on product)

- Bag packer filling capacity: 350 to 4.200 bags/hour (depending on product)

- Products: coarse-grained, poor-flow products

- Product temperature: up to 85°C

- Valve width: 9-13 cm

- Bag lenght: 28-75 cm

- Bag width: 28-51 cm